The Hierarchy of Healthcare Supply Chain Metrics

With the shift toward automated supply chain management (SCM) processes and data capture, the challenge for healthcare supply chain leaders is no longer a lack of metrics at their disposal but rather, confusion around which of the many available metrics they should use.

“Supply chain complexity and the sheer number of metrics available are leading to confusion over using metrics, resulting in poor business decisions,” stated Gartner, citing a survey of supply chain executives where 57% of respondents reported they have too many metrics to track.

To help clear up some of the confusion, let’s define healthcare supply chain metrics, why they are important, and how healthcare supply chain leaders can determine which metrics are most valuable for their organizations to track.

What are Healthcare Supply Chain Metrics?

Healthcare supply chain metrics, also known as key performance indicators (KPI), “enable a supply chain organization to justify, monitor and drive individual processes, as well as accelerate overall supply chain performance by balancing local and global performance improvements,” as described by Gartner.

Why are Healthcare Supply Chain Metrics Important?

Health system and hospital executives are keenly aware of how supply chain performance impacts costs, patient care quality and overall financial outcomes for their organizations.

Today’s supply chain leaders must be strategic in their approach, aligning their work to their healthcare organizations’ overall goals. To do so, they must define what factors of supply chain management impact the organization’s performance, define metrics to measure them and have mechanisms in place to track these metrics over time and adjust as needed.

How to Determine Which Healthcare Supply Chain Metrics are Most Valuable

There are many different sources for healthcare supply chain metrics, including those recommended by industry associations and analysts, and KPIs developed by supply chain leaders based on their own organizational needs.

The Association for Health Care Resource & Materials Management (AHRMM) recently released its Keys for Supply Chain Excellence, which are KPIs that healthcare supply chain leaders can use to “measure performance over time, quantify the value of their organization’s supply chain to executive leadership, and move their supply chain closer to operating from the intersection of Cost, Quality and Outcomes (CQO).” They include metrics spanning finance, operations, patient safety, resiliency, data standards and environmental sustainability.

The AHRMM keys dive down into tactical details, offering equations to calculate performance against these metrics.

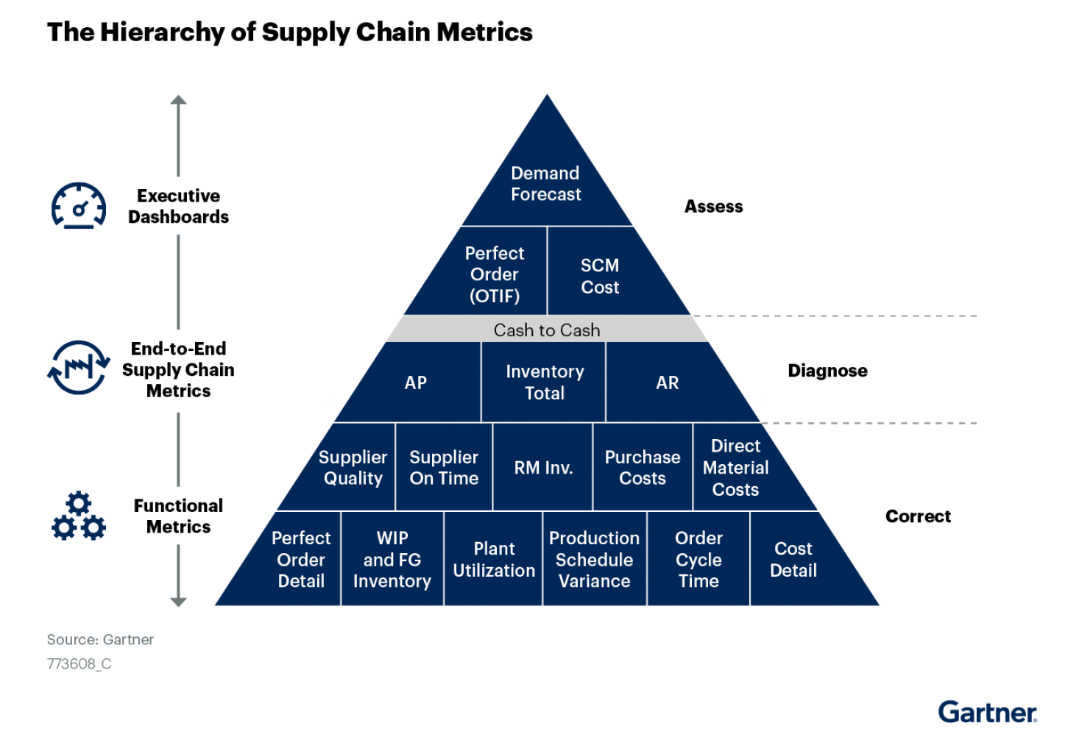

The Gartner Hierarchy of Supply Chain Metrics is another framework that healthcare supply chain leaders can leverage to identify actionable KPIs.

The Gartner Hierarchy of Supply Chain Metrics is another framework that healthcare supply chain leaders can leverage to identify actionable KPIs.

It has “long been regarded as the industry standard for end-to-end supply chain performance measurement,” with Gartner making regular updates to maintain their relevancy. The graphic depicts the latest version, published in October 2022:

At a high level, the hierarchy categorizes three tiers of metrics, each serving a different purpose and aimed at a different goal:

- Top tier – Supply chain health assessment: Three metrics, usually used for executive-level dashboards, to help leaders assess the overall health of the supply chain and the high-level trade-offs a company might be making.

- Mid-tier – Supply chain diagnostic: A composite cash-flow metric to provide an initial diagnostic.

- Bottom tier – Supply chain correction: A variety of functional metrics to support effective root-cause analysis and allow surgical, highly efficient corrective action.

As Gartner explains, a user can leverage this tool to create their own hierarchy of supply chain metrics to assess, diagnose and correct by selecting those “aligned with their corporate strategic priorities and objectives.”

Healthcare Supply Chain Metrics You Should Track

Healthcare supply chain leaders can leverage both the Gartner Hierarchy of Supply Chain Metrics and AHRMM Keys for Supply Chain Excellence to define and track KPIs most impactful to their organizations. The methodologies complement one another, with Gartner offering a high-level view of supply chain metrics and AHRMM presenting a deeper dive into metrics most relevant to healthcare organizations.

While each healthcare supply chain leader should choose KPIs that align with their individual healthcare organization goals, here is an example of how they could blend the Gartner and AHRMM methodologies to establish a hierarchy that measures supply chain management costs.

Metrics from Gartner hierarchy:

- Assess SCM Cost

- Diagnose Accounts Payable (AP)

- Correct Perfect Order Detail

Metric #1: Supply Chain Labor Expense Per Case Mix Index Adjusted Discharge

This KPI defines the labor cost per discharge for in-house supply chain functions. This unit cost informs the sustainability of supply chain’s cost structure within an organization.

Data inputs:

- Gross outpatient revenue

- Gross inpatient revenue

- Number of inpatient discharges

- Case mix index (CMI)

- Number of CMI adjusted discharges

- Total labor expense

Value: Tracking this labor cost per discharge informs if changes in patient activity are impacting supply chain labor costs.

Metric #2: Supply Accounts Payable Days

Measures how effectively the healthcare organization is managing its payables. May be utilized to ensure discounts are optimized, as well as provide greater insight into payment trends and cash flow fluctuations.

Data inputs:

- Total supply expense

- Opening AP dollars

- Closing AP dollars

Value: May be utilized to ensure discounts are optimized, as well as provide greater insight into payment trends and cash flow fluctuations.

Metric #3: Perfect Order

Perfect order is a composite metric that serves to measure the process by which a purchase order (PO) electronically occurs — from order to payment — without human intervention to ensure it is delivered to the correct location, on time, undamaged, at the correct price with the desired quantity, all on the first attempt.

Data inputs:

- Total number of POs sent to all distributors and suppliers

- Number of POs delivered on time

- Number of POs shipped complete

- Number of POs shipped damage free

- Number of POs successfully three-way matched against the receiver and invoice

Value: Perfect order enables performance measurement to cut across functional silos, while also allowing a multi-level view of results; facilitates analysis of performance failures to provide insight into failure patterns and trends, which can then be targeted as part of continuous improvement efforts; and helps galvanize collaboration across the internal/external organizations collectively responsible for supply chain performance.

The Value of Supply Chain Metrics

Today, healthcare supply chain management is a blend of strategy and science. Healthcare supply chain metrics are a key component of setting impactful goals, measuring actionable improvements and demonstrating to leaders the critical importance of supply chain to long-term clinical, operational and financial success.