How to Choose a Warehouse Management System

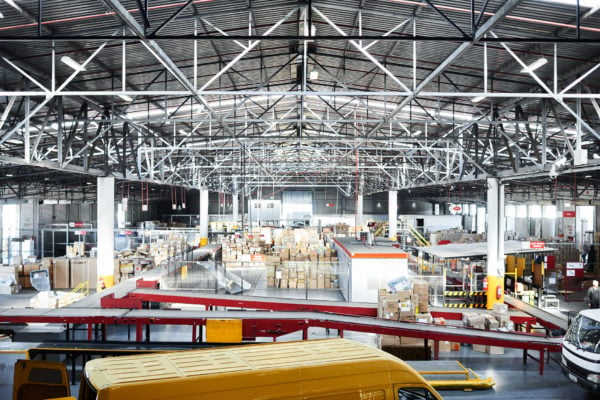

Choosing a warehouse management system (WMS) is a key decision that you will have to live with for years to come. Not only that, but because the whole warehouse system marketplace has evolved significantly in recent years, you’ll want to be thorough in your research rather than make a snap decision.

At last year’s Gartner Supply Chain Executive Symposium, Dwight Klappich, a vice president analyst at Gartner, commented on how, “The WMS market is very mature, being first introduced more than 40 years ago. But WMS providers continue to innovate and we are seeing the rise of the smart warehouse.” Klappich further noted that until recently, “There wasn’t a lot of management in Warehouse Management Systems,” with the systems focused on execution – but he says that is changing.

Today, many industries are challenged by an increasingly dynamic distribution and fulfillment environment. Selecting a WMS can help resolve many pain points in your operations. Let’s look at five key questions that will help you paint a clearer picture of how to choose a warehouse management system.

5 Questions to Ask When Choosing a Warehouse Management System

1. What are the problems you want to solve?

You may need to choose a WMS for many reasons, but there is likely one or two compelling issues that are forcing you to make this investment. Perhaps you are ready to move away from a legacy system or your operations have grown in scope and complexity. These issues will be top-of-mind when looking for a warehouse management system. Document all the key processes and operations that you need a WMS to manage and match those up against your list of contending systems. If you are replacing one WMS for a newer WMS, make sure you consider the things that your current system does well because you’ll want to ensure the new system performs equally as well, if not better. Oftentimes, the simple exercise of documenting your organization’s needs and wants provides you the opportunity to rethink your warehouse operations and determine how a WMS can help you eliminate inefficiencies, improve order accuracy and attain high levels of service.

2. What challenges is your warehouse going to face in the future?

Reach out to all the key business leaders and discuss likely growth or changes in the overall business. These future plans will most likely have implications on your warehouse. You must take these into account and determine what challenges it will bring to your warehouse operations. Knowing these potential challenges now as you are in the process of choosing a WMS will be helpful in your selection process. The right WMS should be both customizable and flexible enough to resolve your challenges now and in the future.

3. What special or unique needs does your business have today or in the coming years?

If you are in an industry that is highly regulated or have customers that demand very specific services or levels of responsiveness, then you’ll also want to prepare for potential challenges these areas may bring to your warehouse operations in the future. Talk to your peers, customers, analysts and even potential vendors about what they are seeing in the market now and in the coming years. Create a shortlist of key factors, specific to your business, that need to be supported. An example of this is the distribution of pharmaceuticals. You need to ensure your potential WMS partner understands DSCSA, 340B, etc. Any regulations you have in your business need to be understood and documented by your WMS.

4. How much can your team take on versus how much are you looking for the vendor to handle?

One area where many warehouse system implementations fail is on the breakout of responsibility of work. When you are choosing a warehouse management system, make sure part of your conversation with prospective partners is defining who will be responsible for data cleansing, defining standard operating procedures (SOPs) for the warehouse, training staff and so on. This cannot go undiscussed since it can lead to huge growth in costs if your vendor expects you to do all the heavy lifting throughout the implementation and you are expecting them to do the work.

5. What is the culture of your company?

Choosing a WMS is not just about getting the right product for your business. Yes, that’s a big factor, but you want a partner that is easy to work with and meets your company culture the best. Most modern warehouse management systems have the same core capabilities, but the nuances are in what extra features and value can you get and how that partner connects with your team. When you pick the right partner, you just know it and things tend to go smoothly, even when there are bumps along the road.

Involve the Right Individuals and Pay Attention to the Details

My final thoughts on when you are choosing a warehouse management system is that you are most likely considering a cloud-based SaaS WMS that continually updates and is managed outside your normal on-premise infrastructure. This means that the responsibility for selecting the right warehouse management system is far less an IT decision and far more in the hands of the operations staff.

Making a well-informed decision about your next WMS will provide you with a runway for grow and adaptability for years to come. Unfortunately, making the wrong choice can leave you unable to respond to the evolving needs of your business and supply chain. Take your time, pay attention to the details and trust your instincts about the partner you would like to work with.